Durable | Sustainable | Beautiful

Architects have been enamored of concrete’s beauty for a very long time; the general public – not so much. Never mind that Pliny the Elder praised the virtues of Roman “Opus caementum” in monumental constructions of the 1st century CE, “It looks unfinished” was a typical lament of the consumer of the vernacular, particularly up until the turn of the 21st century. Then came finishing techniques, densifiers and sealers that made concrete counters, tabletops, and floors chic, if only because their finishes afforded them looks that were less like concrete and more like stone.

Today, contractors can transform a once-utilitarian factory floor into a dramatic walking surface for lobbies and lofts. With a substantial history of successful adaptive re-use projects, the architectural team at Trivers Associates specifies the latest in proven techniques and materials to leverage the value potential of century-old concrete slabs into distinctive designs.

“Concrete Polishing” is commonly used to refer to changing an existing concrete surface by means of a mechanical process involving cutting and/or refining the surface to a desired finish. However, the correct terminology is “Concrete Processing,” as not all processed concrete can be called “polished” (if, for example, only Grinding and Honing steps are undertaken).

There are three fundamental visual aspects of a processed concrete floor finish – surface cut (i.e. degree of aggregate exposure), reflection (degree of polish), and enhancements, if any (stains, dyes, saw-cut patterns).

Finishing levels – basic, medium and premium – drive the amount of work entailed, both in terms of aggregate exposure and reflection/sheen.

Basic-level grind-finish

Medium-level honed-finished

Premium-level polished

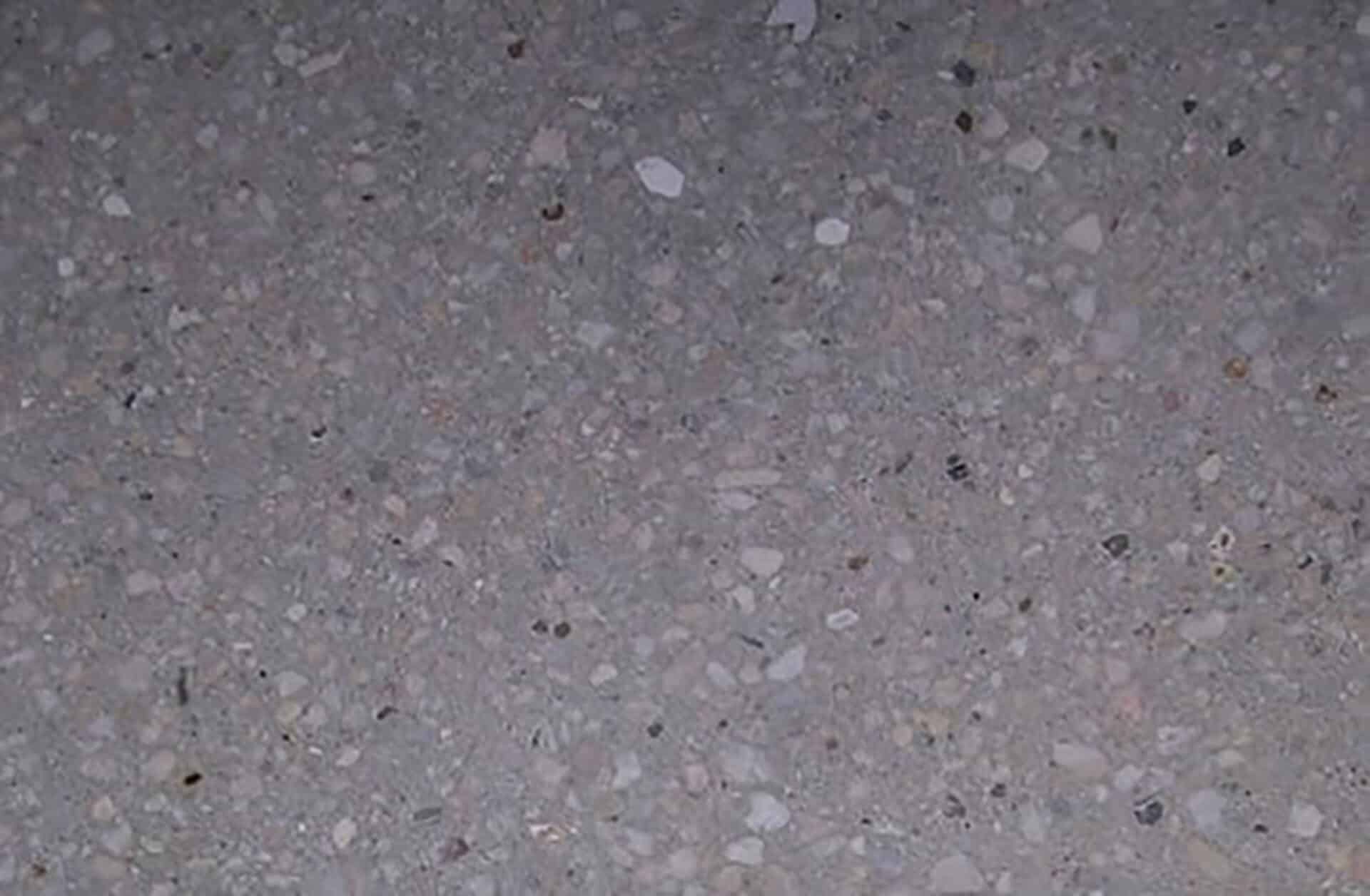

AGGREGATE EXPOSURE CLASS

AGGREGATE EXPOSURE EXAMPLES

Class A- Cream Exposure

Class B- Fine Aggregate (Salt & Pepper) Exposure

Class C- Medium Aggregate Exposure

Class D- Large Aggregate Exposure

GLOSS LEVELS

DENSIFIERS

Densifiers are water-based chemical solutions that first work by penetrating into the surface of the concrete and reacting with calcium hydroxide to produce calcium silicate hydrate (CSH). The CSH that is produced fills the open pores of the concrete, increasing its density. The three types of densifier most commonly used are- sodium, potassium, and lithium. Lithium-silicates penetrate without scrubbing or adding large amounts of water. This saves time, money and energy. They also penetrate completely, which eliminates flushing, waste containment, collection, and disposal—and their costs.

Variables within a concrete processing contractor’s control:

- Equipment

- Weight, RPMs, speed at which machine moves over surface in a linear motion.

- Abrasives

- Configuration of diamonds’ face/tread

- Saturation of diamond grit in the bonding

- Hardness of diamond bonding

- Point at which operators switch abrasives

- Densifiers

- When applied

- What type

- Physical grinding, honing, and polishing

- Degree to which the concrete surface is cut

- Level of clarity of the cut surface

- Refinement of the concrete from one grit to the next

- How well the floor is cleaned between each grit adhesive

Variables of Existing Conditions not within a processing concrete contractor’s control:

- Concrete Surface

- PSI

- Imperfections that need to be removed

- Surface flatness and levelness

- Presence of coatings, glues or mastics

- Finish: hand-troweled or mechanically-troweled

- Concrete Mix Design

- Aggregate

PROCESSED CONCRETE FLOOR FINISHING – THE SUSTAINABLE CHOICE

Going forward, exposing and processing existing concrete floor slabs will increasingly be among the most popular value-added choices available in adaptive re-use buildings. Trivers Associates stands committed to delivering current and reliable specifications and detailing of this environmentally responsible process.